Page Contents

1. Purpose

To provide cleaning instruction of HVAC & various types of filters in AHU as per safety and cGMP requirements

2. Scope

This SOP covers the instructions for cleaning of pre-filters and fine filters of all AHU.

3. Responsibility

HVAC Operator

Maintenace Incharge

Production manager

Quality assurance officer

4. Cleaning Procedure OF HVAC UNIT

Ensure prior to clean

- Ensure that area connected to respective AHU is not in any use by its respective user department

- Intimate user department.

- Stop the respective AHU and remove its fuses and put a board “EQUIPMENT IS UNDER MAINTENANCE” on the AHU.

- By pressing the local push button, ensure the respective AHU can not be started.

Cleaning Procedure for pre-filter and fine filter:

- Remove the filters to be cleaned from the AHU by unscrewing all its bolts.

- Number the filters with marker pen as per its original location so that they can be refixed on their same location.

- Take all the filters to the filter cleaning room.

- Wear rubber gloves and eye goggles.

- Spray compressed air on the filter in the direction opposite to the air flow direction when the AHU is under working condition. Continue this process as per requirement of cleaning. Maintain air pressure in the range of 2 to 3 kg/cm2 g.

- Then clean the filters with the help of tap water.

- Then again spray compressed air on the filter in both the directions. Continue this spray unless all the water is removed from the filter and filter is thoroughly clean.

- Keep the cleaned filter on the rack for drying for 1 to 1.5 hrs

- Also clean all the section of AHU like return air section, supply air section, fan – motor section, cooling coil section and all the sides of AHU by cotton dipped in potable water and final drying using dry cotton waste

- Refix all the filters as per its number on their original position.

- Also, clean the filter cleaning room.

- Insert the fuses of the AHU and ensure that there is no leakage by physical checking from any side of the filters.

5. Perdioc Maintenance Of HVAC Uunit

The following checklist describes the suggested maintenance schedule to maintain the proper operation of the unit. Detailed procedures for owner-operator are given after this checklist.

Every Month

- Inspect air filters. Clean or replace if clogged,

- Inspect air filter manometer for bad filters or roll filters with manual controls. Change bag filters when manometer reading is 1-inch wg. Change roll filters when manometer reading is ½ inch wg,

- Check sump water concentration in sprayed coil units to make sure no corrosive or scaling conditions have been created by poorly treated water.

Every Three to Six Months:

Note: The procedures listed in this section should be completed every three to six months. The frequency of their operations will depend on ambient and load conditions. Detailed procedures following this procedure will give more information on suggested conditions and schedules.

- Check that fan bearing grease lines are tight to the bearing so no grease leaks at the connection,

- Lubricate fan bearings,

- Check bearing locking setscrews and other setscrews for proper tightness. All bearing races must be secure,

- Lubricate fan motors,

- Align sheaves and level of shafts,

- Check fan belt tension. Adjust if belt slip. Replace worm of frayed belts with a new matched set,

- Inspect coils for frost or dirt built up. Clean fins if air flow is clogged,

- Inspect spray humidifier for lime deposits in the spray nozzle. Clean if the flow is clogged,

- Inspect steam grid humidifier wrapping. Replace if flow is clogged.

Every year:

- Inspect electrical wiring for condition. Tighten all connections,

- Inspect the unit casing and accessories for chipping or corrosion. If damage is found, clean and repaint with a good grade of rust resistant Zinc Chromate Paint,

- Clean fan wheels and fan shaft. Remove rust from fan shaft with an emery cloth and re-coat the shaft with L.P.S. 3 or equivalent,

- Inspect the drainpipe for sludge or other foreign material. Clear the drain openings and drain line to ensure adequate flow,

- Check damper linkages, setscrews and blade adjustments for proper tightness and operation. Do not lubricate nylon damper rod bushings,

- Check inlet vane linkages, setscrews and vane adjustment for proper tightness, operation and alignment,

- Recalibrate the filter manometer,

- Clean and check the water system on sprayed coil climate chargers.

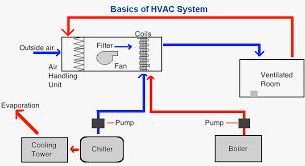

The organization has determined and managed the entire work environment like temperature and relative humidity controls, which are required for manufacturing of quality products.

These conditions are being maintained by comprehensive Air Handling System.

5. Safety, Health and Environmental Aspects

5.1 Before cleaning the filter:

5.2 Wear rubber gloves and eye goggles.

5.3 Remove the fuses of the respective AHU

5.4 Put a board on the AHU that “AHU IS UNDER MAINTENANCE.”